- Product Introduction

- Chain Parameters

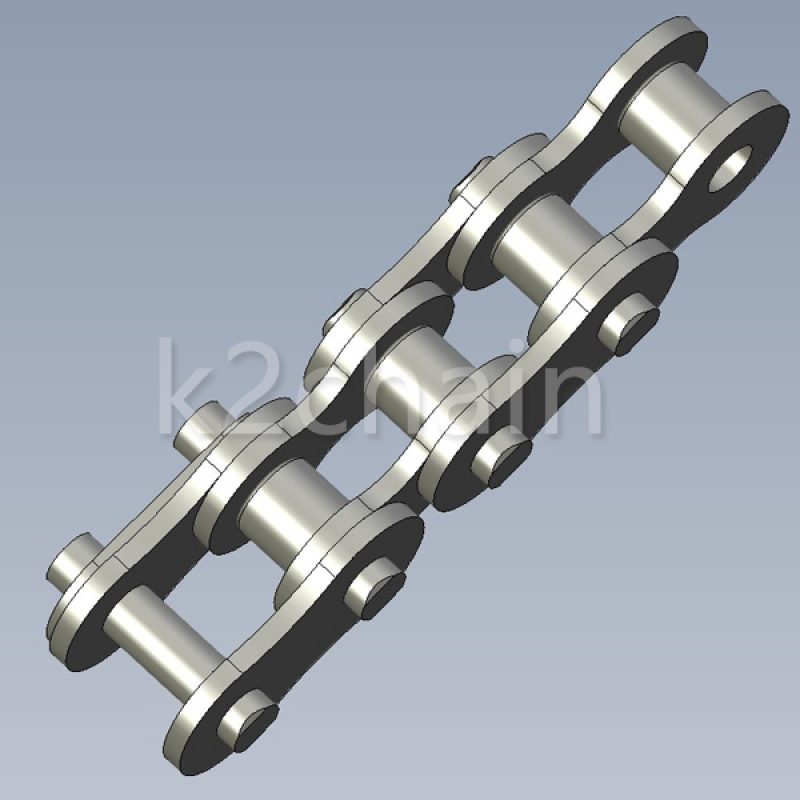

Series A roller chains for transmission are renowned for their high strength and long-lasting fatigue resistance. Their dimensions fully comply with ANSI standards and can be assembled into single-row, double-row, and multi-row configurations to adapt to the transmitted power and different installation spaces.

Based on various working environments, chains with different surface coating treatments such as galvanizing, nickel plating, chrome plating, and Dacromet are available. All surface treatment methods are free of hexavalent chromium.

Building on the foundation of transmission roller chains, various attachments such as Type A, SA, K, SK, and D are installed according to application requirements, forming the most widely used chain products in the material conveying field, which are suitable for the diverse needs of different industrial sectors.

Experimental data shows that chain wear is related to the selection of lubricating oil. Kai Transmission provides a rust-proof oil film on the surface of roller chains at the time of delivery, which can achieve long-term lubrication and friction reduction effects. Moreover, its quality complies with the EU REACH regulation, making it more environmentally friendly.

Simplex roller chains & bush chains

ISO/ANSI/DIN Chain No. | Pitch | Roller diameter | Width between innerplate | Pin diameter | Pin length | Inner plate depth | Plate thickness | Tensile strength | Average tensile strength | Weight per meter | ||

| Keai Chain No. | P mm | d1 max mm | d2 max mm | d2 max mm | L max mm | Lc max mm | h2 max mm | t/T max mm | Q min kN/df | Qo kN | q kg/m | |

| 15 | *03C | 4.7625 | 2.48 | 2.38 | 1.62 | 6.1 | 6.9 | 4.3 | 0.6 | 1.80/409 | 2 | 0.08 |

| *25 | *04C-1 | 6.35 | 3.3 | 3.18 | 2.31 | 7.9 | 8.4 | 6 | 0.8 | 3.50/795 | 5 | 0.15 |

| *35 | *06C-1 | 9.525 | 5.08 | 4.77 | 3.58 | 12.4 | 13.17 | 9 | 1.3 | 7.90/1795 | 11.3 | 0.33 |

| 41 | 085-1 | 12.7 | 7.77 | 6.25 | 3.58 | 13.75 | 15 | 9.91 | 1.3 | 6.67/1516 | 12.6 | 0.41 |

| 40 | 08A-1 | 12.7 | 7.95 | 7.85 | 3.96 | 16.6 | 17.8 | 12 | 1.5 | 14.10/3205 | 18.6 | 0.62 |

| 50 | 10A-1 | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 22.2 | 15.09 | 2.03 | 22.20/5045 | 31.3 | 1.02 |

| 60 | 12A-1 | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 27.7 | 18 | 2.42 | 31.80/7227 | 43.2 | 1.5 |

| 80 | 16A-1 | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 35 | 24 | 3.25 | 56.70/12886 | 74.3 | 2.6 |

| 100 | 20A-1 | 31.75 | 19.05 | 18.9 | 9.53 | 40.4 | 44.7 | 30 | 4 | 88.50/20114 | 107.6 | 3.91 |

| 120 | 24A-1 | 38.1 | 22.23 | 25.22 | 11.1 | 50.3 | 54.3 | 35.7 | 4.8 | 127.00/28864 | 163.1 | 5.62 |

| 140 | 28A-1 | 44.45 | 25.4 | 25.22 | 12.7 | 54.4 | 59 | 41 | 5.6 | 172.40/39182 | 222.5 | 7.5 |

| 160 | 32A-1 | 50.8 | 28.58 | 31.55 | 14.27 | 64.8 | 69.6 | 47.8 | 6.4 | 226.80/51545 | 266.9 | 10.1 |

| 180 | 36A-1 | 57.15 | 35.71 | 35.48 | 17.46 | 72.8 | 78.6 | 53.6 | 7.2 | 280.20/63682 | 361.1 | 13.45 |

| 200 | 40A-1 | 63.5 | 39.68 | 37.85 | 19.85 | 80.3 | 87.2 | 60 | 8 | 353.80/80409 | 466.8 | 16.15 |

| 240 | 48A-1 | 76.2 | 47.63 | 47.35 | 23.81 | 95.5 | 103 | 72.39 | 9.5 | 510.30/115977 | 671.6 | 23.2 |